The increasing of information stream due to digitalization and accessibility to information sources, has led to numerous debates in the oil markets. Refiners, traders, brokers, end-consumers and all other stakeholders within the industry need to cope with decision making on various levels and are therefore relying on certain proved sources in an industry which is full of closed doors and limited availability of information. Transparency in this market is therefore crucial to search and select the appropriate partners within the market and to make smarter business decisions.

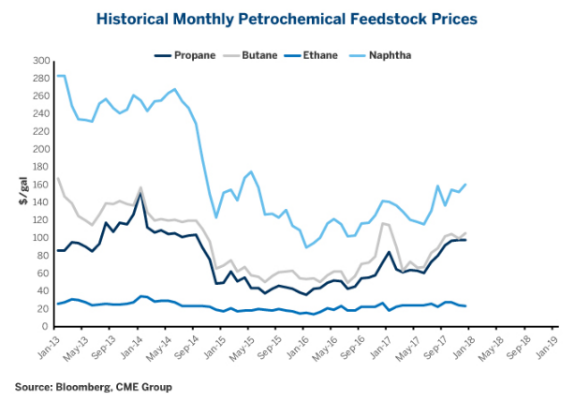

Market transparency can be found in all different subjects within the oil and gas industry. Price setting agencies, transport and tank storage rates overviews and other statistical insights contribute to a level playing field, which can help the customer make the best decision possible. By obtaining instantly accurate information, one can reduce mainly costs, time and effort. Objective players in the oil and gas environment, help balance the markets by supplying vast amounts of data and information to all participants. Traders interpret the macro-economic data of NGOs, governmental institutions and central banks to weight their decisions and therefore depend on reliable information. Falsified or incorrect information can give individuals an edge and increases the costs involved for the other businesses.

Moreover, these objective market participants withhold fraudulent companies or individuals from entering and disbalancing the market. Associations such as, FERM Rotterdam (ferm-rotterdam.nl) provide insights over the fake suppliers of tank storage capacity, in order to limit the risks involved for other market participants. Individuals without proper knowledge of the markets, can easily become targets of these scams. Who is able to spot the differences when certain, legitimately looking, websites come across?

For businesses entering the market, these organizations are key to a fruitful collaboration between suppliers and clients. In addition, these organizations show which websites, companies or individuals to bypass. Companies and terminals in the TankTerminals.com database are investigated by various database administrators before being added in the vast database of terminal details, characteristics, contacts and other relevant information. Data supplied by the terminals and the managers of the terminals is thoroughly checked before it is approved. The data is regularly updated and if possible expanded with more data to give a transparent overview on the tank terminals. This way, potential suppliers, customers and others interested have a quick go-to list which reduces the efforts of going through all kind of information. The completer the information in the terminal factsheets, the higher the reliability, legitimacy and opportunities to connect with the relevant contacts.

Market transparency is imperative in getting quickly the right information and with as little errors as possible. The oil and gas industry and its environment has been closed and constrained. However, it is rapidly changing in the digital age with the help of different organizations. The information, statistics and other relevant news can be supplied to the interested individuals and companies in order to get more insights, to make quicker and smarter decisions.

Author: Lars van Wageningen