From the moment that China offered Saudi Crown Prince Mohammed bin Salman (MbS) a face-saving way out of the Saudi Aramco initial public offering disaster that he had created, as analysed in depth in my new book on the new global oil market order, the relationship between the two countries has grown ever stronger.

Toward the end of last year, Saudi Arabia reiterated its commitment to China as its “most reliable partner and supplier of crude oil,” along with broader assurances of its ongoing support in several other areas.

This followed the comment in March 2021 at the annual China Development Forum hosted in Beijing, from Aramco chief executive officer, Amin Nasser that: “Ensuring the continuing security of China’s energy needs remains our highest priority – not just for the next five years but for the next 50 and beyond.”

Such statements appeared to confirm that MbS now sees the U.S. as a partner just for its security considerations in the new global oil market order, with no meaningful quid pro quo on Saudi Arabia’s part, whilst regarding China as its key partner economically and Russia as its key partner in energy matters. A slew of new commitments last week from Saudi Arabia to China appear to confirm these views.

To begin with, Saudi Arabia’s energy minister Prince Abdulaziz bin Salman said that the Kingdom is keen to cooperate further with China in developing gas ties, as well as those relating to crude oil.

These gas ties will span the entire sector, from the development of reserves to new petrochemicals projects, and follow on from the signing last August of a multi-pronged memorandum of understanding (MoU) between Saudi Aramco and the China Petroleum & Chemical Corporation (Sinopec). As the president of Sinopec, Yu Baocai, put it at the time: “The signing of the MoU introduces a new chapter of our partnership in the Kingdom [of Saudi Aabia] …The two companies will join hands in renewing the vitality and scoring new progress of the Belt and Road Initiative [BRI] and [Saudi Arabia’s] Vision 2030.”

Crucially for China’s long-term plans in Saudi Arabia, it also covers opportunities for the construction of a huge manufacturing hub in King Salman Energy Park that will involve the ongoing, on-the-ground presence on Saudi Arabian soil of significant numbers of Chinese personnel.

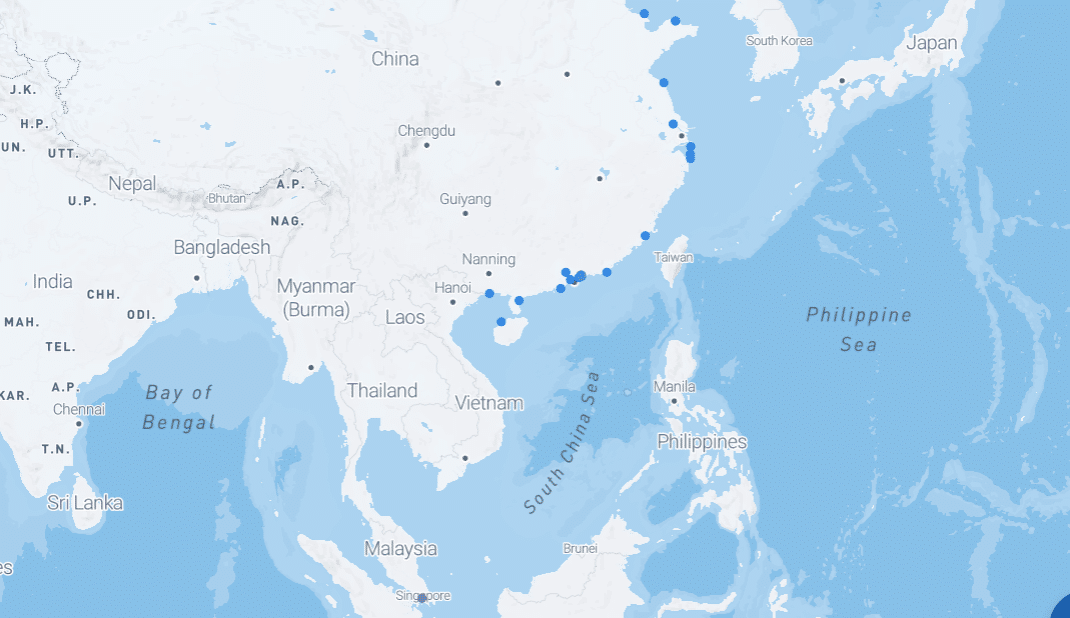

These will not just be directly related to the oil, gas, petrochemicals, and other hydrocarbons activities, but will also include a small army of security personnel to ensure the safety of China’s investments. At that point last year, Aramco already had a 25 percent stake in the 280,000 barrels per day (bpd) Fujian refinery in south China through a joint venture with Sinopec (and the U.S.’s ExxonMobil) and had also earlier agreed (in 2018) to buy a 9 percent stake in China’s 800,000 bpd ZPC refinery from Rongsheng.

Several other joint projects between China and Saudi Arabia that had been agreed in principle had been delayed due to a combination of factors at the time. These were the ongoing effects of COVID-19, Aramco’s crushing dividend repayment schedule, and concern from both countries – especially China – on how Washington might react to this clear threat to the U.S.’s own long-running relationship with Saudi Arabia, as also analysed in depth in my new book on the new global oil market order.

The basis of this enduring relationship had been struck back in 1945 at a meeting on 14 February 1945 between the then-U.S. President Franklin D. Roosevelt and the Saudi King at the time, Abdulaziz bin Abdul Rahman Al Saud. The deal that they agreed – which had been the basis for all the U.S.’s Middle East policy up until very recently – was this: the U.S. would receive all of the oil supplies it needed for as long as Saudi had oil in place, in return for which the U.S. would guarantee the security both of the ruling House of Saud and, by extension, of Saudi Arabia. This landmark deal survived the 1973 Oil Crisis and even looked as though it might survive the Saudi-led Oil Price War from 2014 to 2016, aimed by Riyadh at destroying or at least severely disabling the then-nascent U.S. shale oil industry. The real death of the 1945 Bitter Lake deal came when Russia emerged at the end of 2016 to support the then-beleaguered Saudi Arabia and OPEC in future oil production deals, given the lack of credibility in the global oil markets that both had at the end of the 2014-2016 Oil Price War.

With the announcements last week, it seems that all the key elements of the previously-announced deals between Saudi Arabia and China are coming back into play.

Just prior to the signing of the wide-ranging MoU in August 2022 – the precursor to last week’s agreements – Saudi Aramco’s senior vice president downstream, Mohammed Y. Al Qahtani, announced the creation of a ‘one-stop shop’ provided by his company in China’s Shandong. “The ongoing energy crisis [caused by Russia’s invasion of Ukraine in February 2022], for example, is a direct result of fragile international transition plans which have arbitrarily ignored energy security and affordability for all,” he said. “The world needs clear-eyed thinking on such issues – that’s why we highly admire China’s 14th Five Year Plan for prioritising energy security and stability, acknowledging its crucial role in economic development,” he added.

The megaproject in Shandong, which is home to around 26 percent of China’s refining capacity and is a key destination for Saudi Aramco’s crude oil exports, will broadly involve the flagship Saudi oil and gas giant creating “stronger ties with the world’s largest oil exporter [that] would enhance China’s energy security, especially as we work on increasing our production capacity to 13 million barrels per day,” according to Al Qahtani. Aside from the fact that Saudi Arabia still cannot produce anywhere near 13 million barrels per day of crude oil, as examined in detail in my new book, closer cooperation between Aramco and China will mean Saudi Arabia investing heavily in the build-out of a large, integrated downstream business across the country in tandem with its Chinese partners.

A key facet of agreements made by emerging nations with China is that they tend to feature significant deal creep. As highlighted above, they all tend to feature the build-out by China of major facilities in the target countries that allow Beijing to station significant numbers of personnel – including those designated as security staff – in and around them. They also tend to act as the precursor to several other more insidious features that only become clearer as time progresses. In December 2022, MbS hosted a series of meetings in Riyadh between China’s President Xi Jinping and the leaders of countries in the Arab League.

The Arab League comprises Algeria, Bahrain, Comoros, Djibouti, Egypt, Iraq, Jordon, Kuwait, Lebanon, Libya, Mauritania, Morocco, Oman, Palestinian Authority, Qatar, Saudi Arabia, Somalia, Sudan, Syria, Tunisia, United Arab Emirates and Yemen. At this meeting – and the January 2022 meeting between senior officials from the Chinese government and foreign ministers from Saudi Arabia, Kuwait, Oman, Bahrain, plus the secretary-general of the Gulf Cooperation Council (comprising Bahrain, Kuwait, Oman, Qatar, Saudi Arabia, and the United Arab Emirates) – the principal topics of conversation were to finally seal a China-GCC Free Trade Agreement and to forge a “deeper strategic cooperation in a region where U.S. dominance is showing signs of retreat”.

Also at the December 2022 meetings, China’s President Xi Jinping identified two ‘priority areas’ that he believed should be addressed as quickly as possible, as also analysed in depth in my new book on the new global oil market order. The first was the transition to using the Chinese renminbi in oil and gas deals done between the Arab League countries and China.

The second was to bring nuclear technology to targeted countries, beginning with Saudi Arabia. Previously, the Kingdom had been in talks to acquire nuclear technology from the U.S. under the ‘1-2-3’ protocol.

As highlighted in 2019 by then-US Energy Secretary, Rick Perry, Saudi Arabia had told the U.S. that it wanted to go ahead with a full-cycle nuclear programme, including the production and enrichment of uranium for atomic fuel. The U.S. had made it clear that for U.S. companies to participate in Saudi Arabia’s project, Riyadh would need to sign an accord on the peaceful use of nuclear technology with Washington. The ‘1-2-3’ protocol was intended to limit the enrichment of uranium for arms purposes.

China does not have such a protocol in place for Saudi Arabia. And, as Saudi Arabia’s energy minister Prince Abdulaziz bin Salman again reiterated last week: “We came to recognise the reality of today that China has taken a lead and will continue to take that lead […] We do not have to compete with China, we have to collaborate with China.”

OilPrice by Simon Watkins, June 28, 2023